# Multiple Order

# The role of warehouse process one (Multiple Order)

- Intelligent, efficient and accurate completion of compound orders

picking,sorting,packingandoutgoing

# Operation process

【Warehouse review】-->【Goods Wait】-->

【Pick Order】-->【Pack Order】-->【Stockout Order】

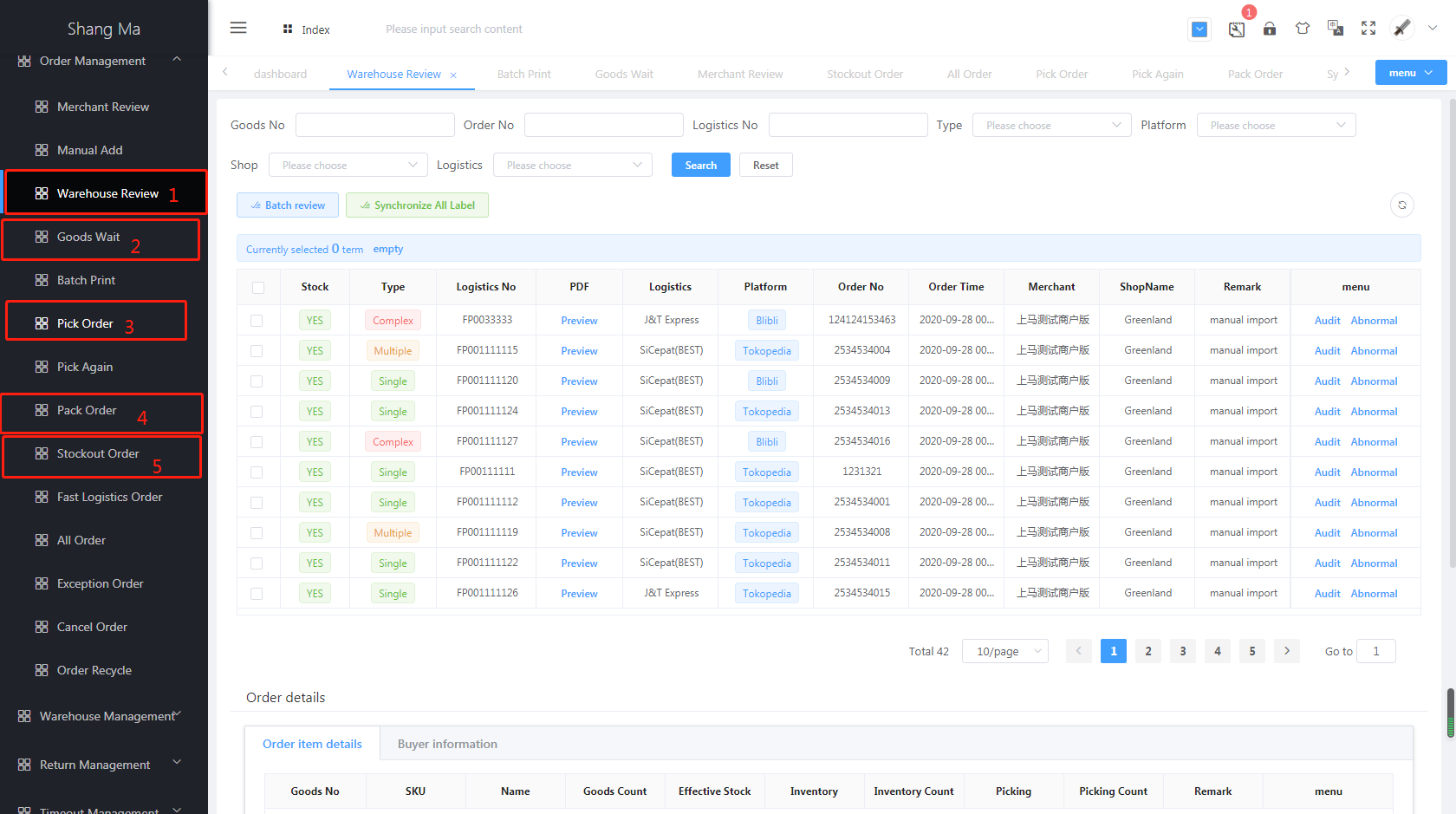

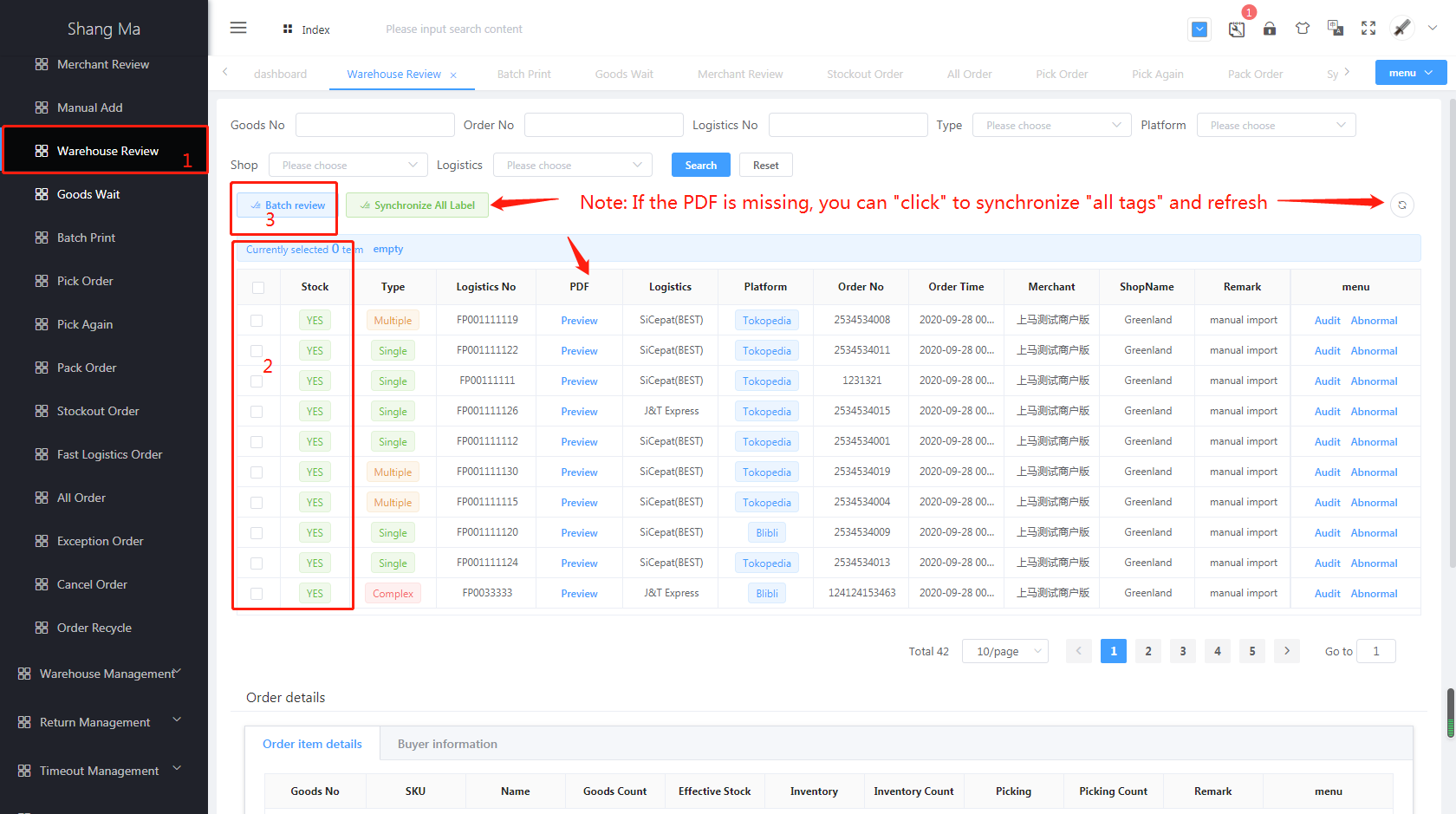

# Step 1: [Warehouse Review]

- Purpose: According to the warehouse delivery priority, review the order

- The operation is as follows:

- Click

Warehouse Review - Select the order that needs to be reviewed (you can select the order by searching)

- Click

Batch Review - Note: If the PDF is missing, you can

clickto synchronizeall tagsand refesh

- Click

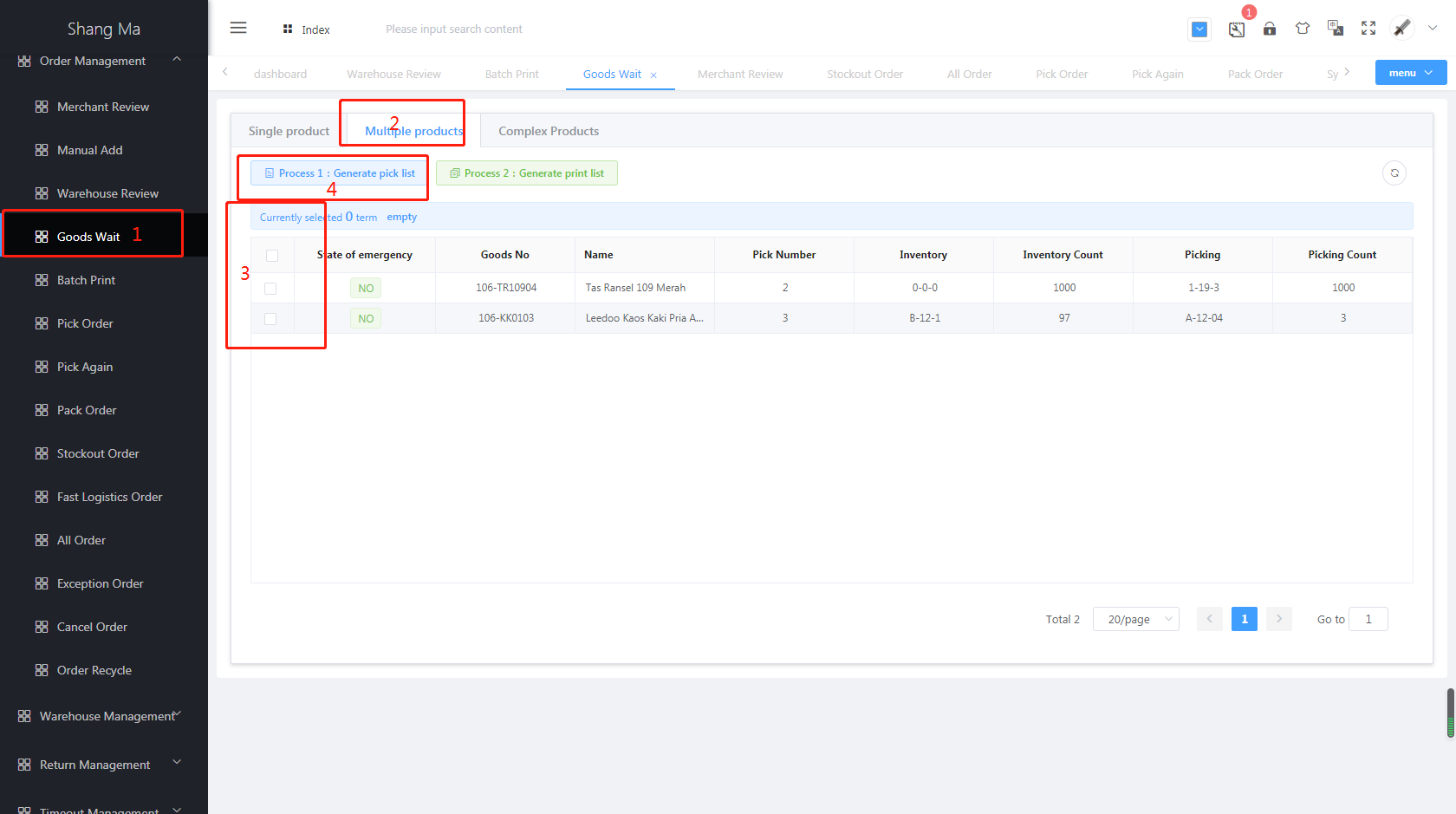

# Step 2:[Goods Wait]

- Purpose: Collect the ordered goods and generate a picking list

- The operation is as follows:

- Click

Goods Wait - Select

Multiple products - Select the product that needs to be picked

- Click

Process 1: Generate Pick List

- Click

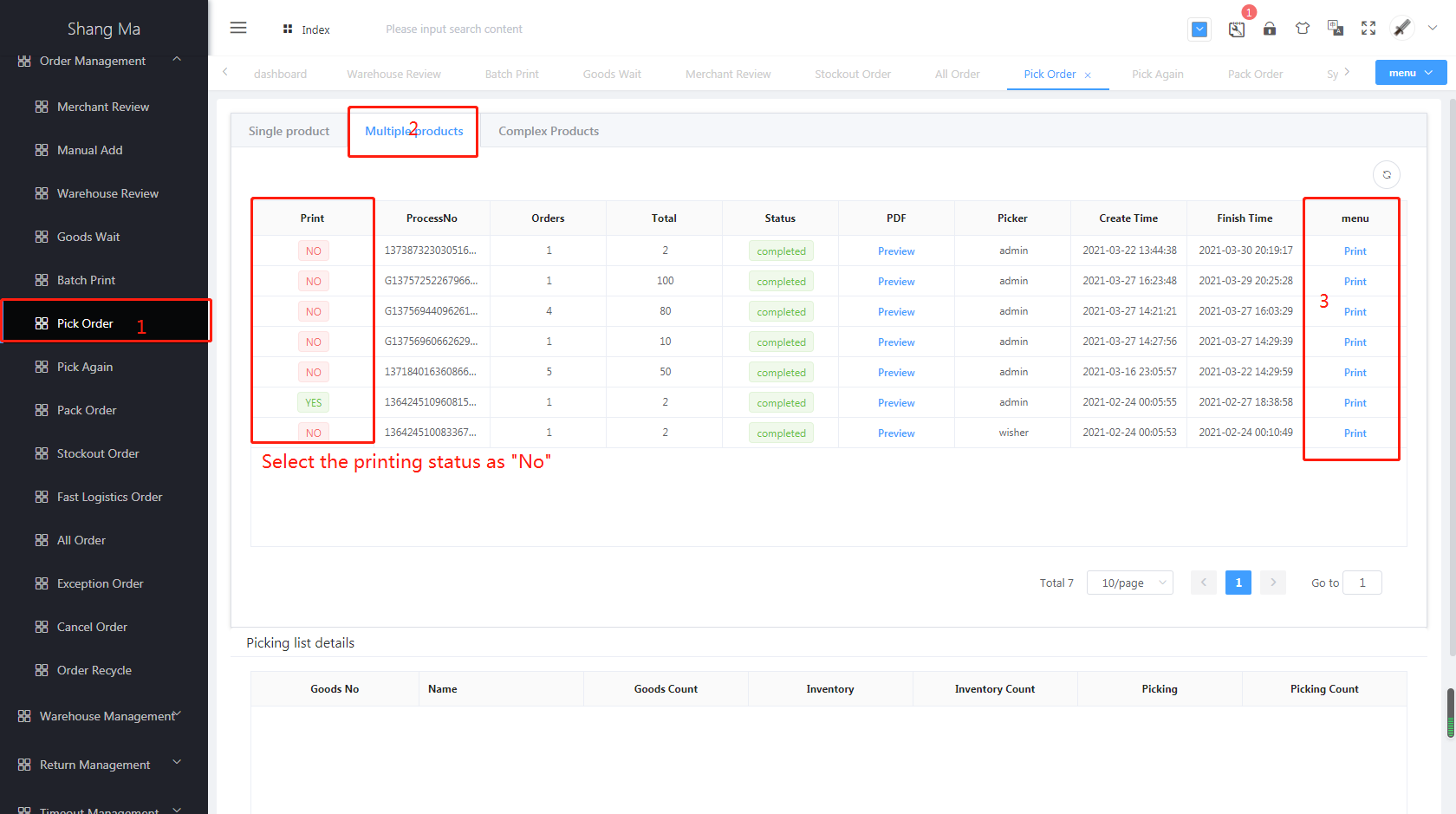

# Step 3: [Pick Order]

- Purpose: Print the picking list

- The operation is as follows:

- Click

Pick Order - Select

Multiple products Printthe corresponding picking list- The picker takes the picking list to pick the goods

- Click

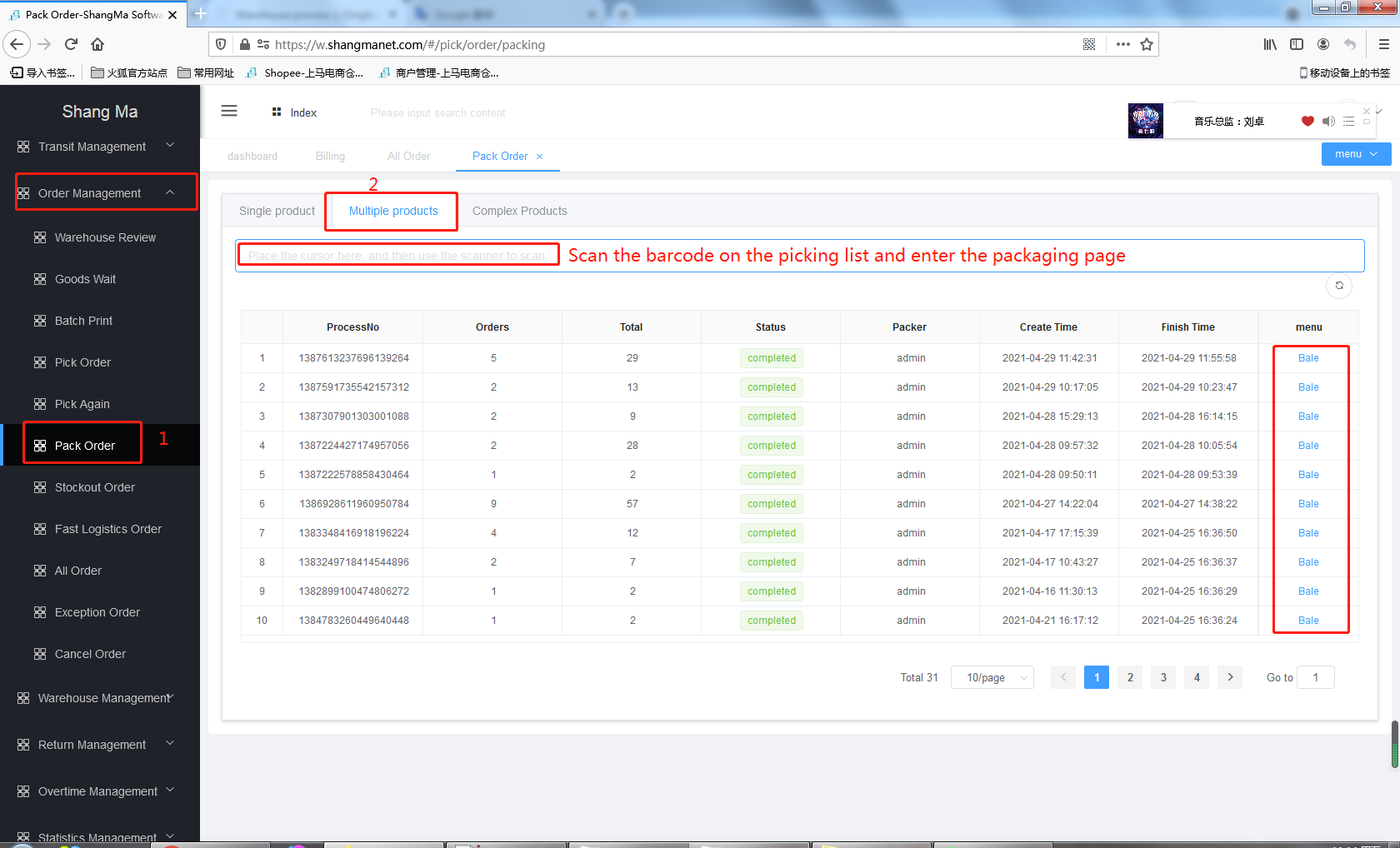

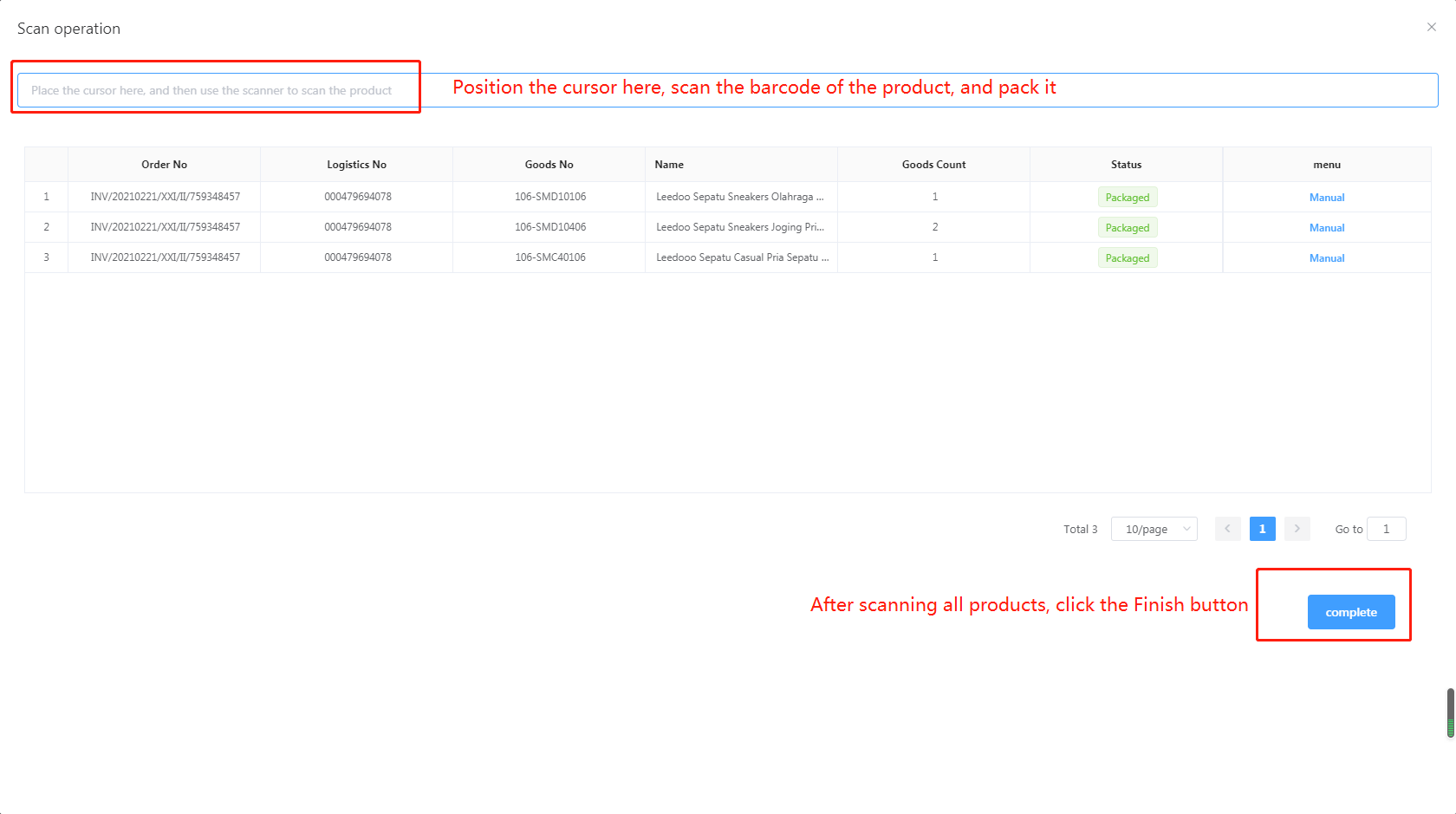

# Step 4: [Pack Order]

- Purpose: Second confirmation, compound order integrity

- The operation is as follows:

Click

Pack OrderSelect

Multiple productsScan the barcode on the picking list and enter the packaging page

Scan the barcode of the product to verify the order product

After scanning all the products, click the

Finishbutton

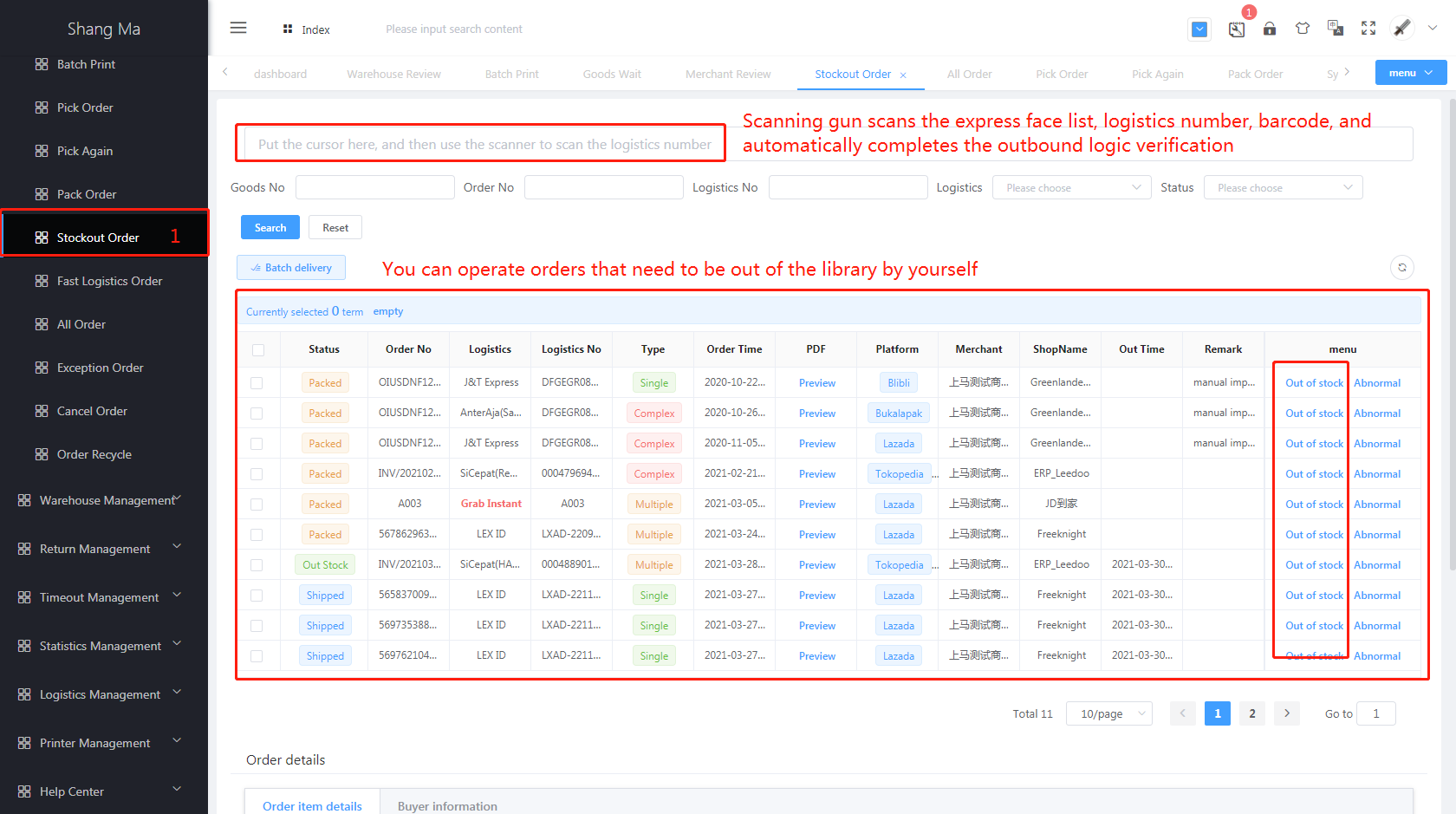

# Step5:[Stockout Order]

- purpose:

- Verify outbound orders and statistical data;

- Prevent cancellation of orders out of the warehouse;

- Pickup urgent orders (Go-JEK; Gosend; Grab, etc.)

- The operation is as follows:

- Click

Stockout Order - Scanning with scanner, express delivery bill, logistics number, barcode, and automatically complete outbound logic verification (packaged orders)

- Click